- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

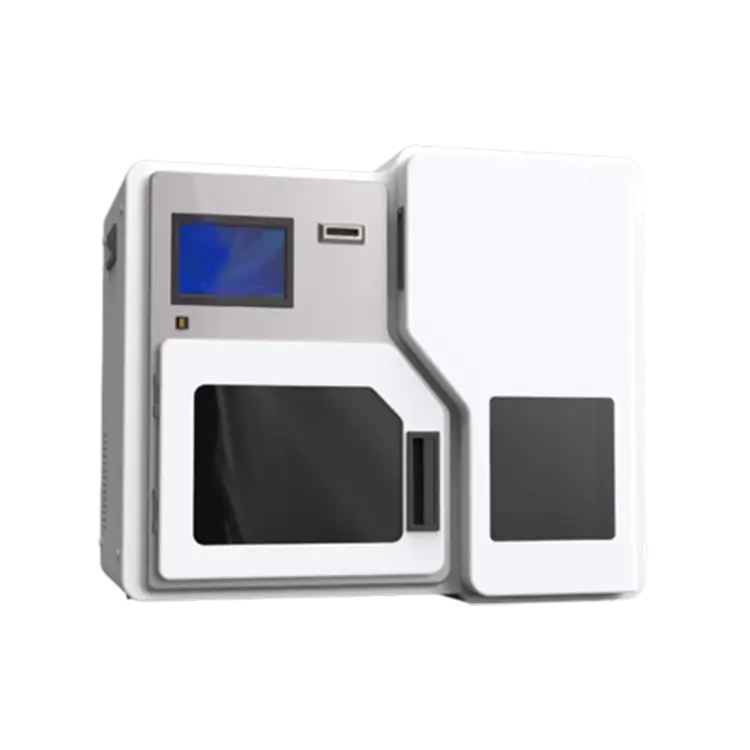

Total Organic Carbon Analyser

TA-201E Total Organic Carbon Analyser adopts the high-temperature catalytic combustion oxidation method, the specimen together with the purification gas (high purity oxygen) are introduced into the high-temperature combustion tube and the low-temperature reaction tube respectively

Model:TA-201E

Send Inquiry

TA-201E Total Organic Carbon Analyser

TA-201E adopts the high-temperature catalytic combustion oxidation method, the specimen together with the purification gas (high purity oxygen) are introduced into the high-temperature combustion tube and the low-temperature reaction tube respectively, the specimen through the high-temperature combustion tube is catalytically oxidised by the high temperature, and the organic carbon and inorganic carbon therein are converted into carbon dioxide, and the inorganic carbon therein is decomposed into carbon dioxide after the acidification of the specimen through the low-temperature reaction tube; the carbon dioxide produced by both reaction tubes is introduced into the non-dispersive infrared gas detector NDIR in turn through carrier gas transport, and COThe carbon dioxide produced in the two reaction tubes is sequentially introduced into the non-dispersive infrared gas detector (NDIR) through gas transport, and CO₂ is detected.Thus, the total carbon (TC) and inorganic carbon (IC) in the water are measured separately.The difference between TC and IC is the total organic carbon (TOC).That is: TOC = TC - IC

Features

1. High-temperature catalytic oxidation can efficiently oxidize difficult-to-digest organic carbon, making the product easy to analyze high-concentration TOC samples;

2. Rapid analysis (1-4 minutes);

3. Higher safety, the combustion furnace heating adopts multiple protections, and the overheating protection circuit is independent of the temperature control system. Overheating can automatically cut off the heating to ensure product safety;

4. Real-time flow monitoring to maintain flow stability and ensure data reliability;

5. The pipeline can be cleaned and purged in all directions. The internal circuit can be cleaned according to the needs and operating requirements, which greatly reduces the failure rate and instrument maintenance time;

6. The instrument automatically discharges waste, automatically discharges and feeds acid, and the acid inlet amount is controlled stably;

7. Less sample and reagent consumption, each measurement requires 0.5μL of high-purity water, 2ml of acid reagent (for IC testing), and about 2000ml of high-purity oxygen (under standard conditions, flow rate 100ml/min, ventilation time 20min.);

8. The CO₂ detection of the NDIR detector has good linearity and high accuracy. The CO₂ signal is converted into a peak curve, and then the built-in data processor calculates the TOC value (the difference between TC and IC);

9. The catalytic combustion oxidation method has strong oxidation ability and can oxidize almost all organic matter with stable performance. The 680℃ combustion method is almost below the melting point of all salts, which can extend the life of the catalyst and combustion tube, which is especially important when the measurement object is a water sample containing salt;

10. The instrument uses a high-resolution 7-inch touch wide screen and adopts an intelligent system for easy operation.

Functional parameters

| Model | TA-201E |

| Measurement range |

0~1000mg/L (non-dilution state), dilution state can reach 0~30000mg/L |

| Repeatability | ≤3% |

| Indication error |

TC: ±0.1%F.S or ±5% (the larger one) IC:±0.1%F.S or ±4% (the larger one) |

| Linearity | R2≥99.9% |

| Lower detection limit | 0.5mg/L |

| Analysis time | 2~4min |

| Injection volume | 10μL~500μL |

| External storage | U disk |

| Power supply | AC 220V±10% 50/60Hz (reliable grounding required) |

| Power | 1000W when the electric furnace is heated |

| Ambient temperature | 0~40℃ |

| Relative humidity | 10~85% |

| Setting location | Indoor |

| Gas source | high-purity oxygen(299.999%) |

| High purity Water | Carbon dioxide-free water(TOC≤0.5mg/L) |

| Acid reagent | 10% phosphoric acid |

| Instrument placement |

There must be 20cm of space around for heat dissipation, and no items can be stacked on top |

| Combustion temperature | 680℃~1200℃ |

Applications

Determination of total organic carbon (TOC) in surface water, groundwater, domestic sewage, industrial wastewater, applied to environmental monitoring, urban water supply and drainage, disease control, chemical power and other industries.